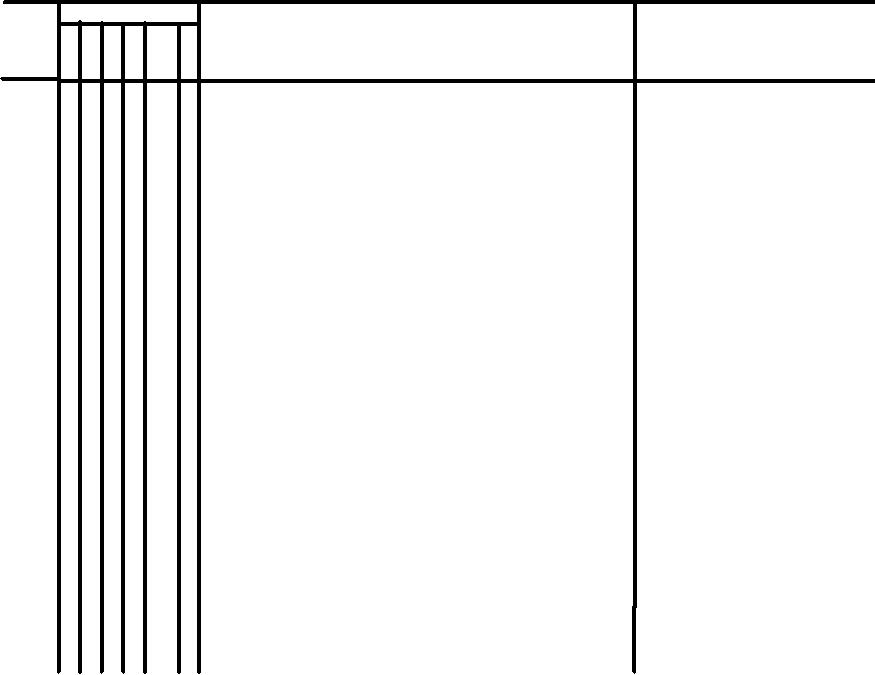

Operator/Crew Preventive Maintenance Checks and Services

B-Before

D-During

A-After

W-Weekly

M-Monthly

Interval

ITEM TO BE INSPECTED

FOR READINESS

REPORTING

Item

Procedure: Check For And Have Repaired,

Equipment is Not Ready

No. Q S A B H

MI

Filled or Adjusted As Needed

Available If:

1.

GENERAL. a) Check for loose wiring

b) Check for damaged piping

c) Check for evidence of fuel leakage (oil, fuel)

2.

Wheel Bearings

Clean and repack(refer to LO)

3.

1000

Gear Reduction Unit (refer to LO)

4.

6000

Pump Motor (refer to LO)

5.

Spring Shackles (refer to LO)

6.

Gages

Check for operation

7.

Drawbar and Frame

Clean and check for excessive wear, corrosion, cracks, bent,

or deformed parts.

8

Circulating Pump Motor

Lighten loose connections, check alignment of motor and pump

drive coupling.

9.

Fuel Oil Strainers

Replace filter elements and gaskets.

10.

*Fuel Oil Pump

Inspect for leaks and operation. Adjust pump pressure (300psi)

if necessary.

F-5