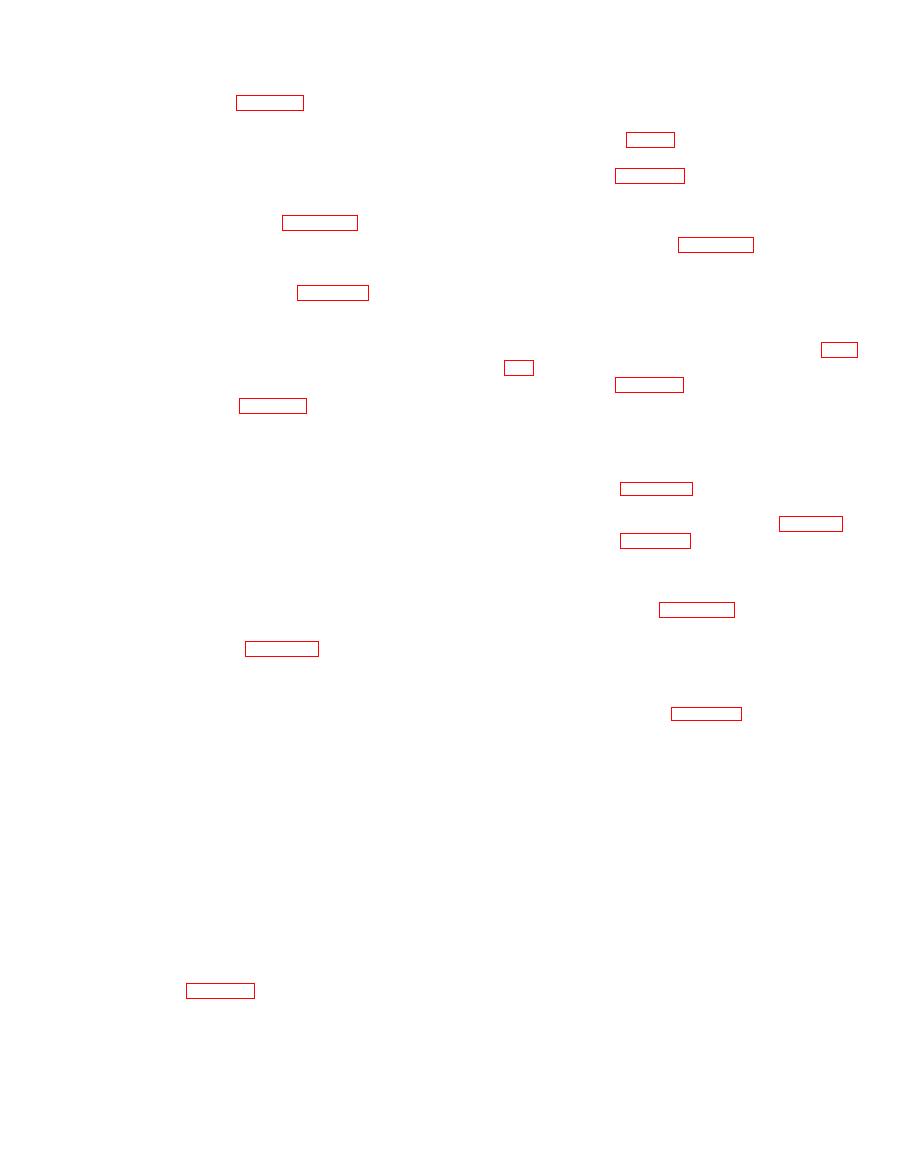

b. Inspection. Inspect hood for distorted condition

and/or a broken hinge. Replace hood as required.

a. General. A cover hole was originally provided

c. Installation.

on the standard models of the tank heaters for the

(1) Refer to figure 5-6 and place the hood (12) on

purpose of adding water to the tank. On the modified

the burner collar (19).

standard models, the hole has beem covered with a

(2) Insert hinge pin (11) and secure it with cotter

thin plate of steel (fig. 5-2).

pin (13).

b. Removal.

(1) Refer to figure 5-2 and remove wingnuts from

the squarehead bolts welded to the under side of the

cover.

(2) Lift off cover.

plug (4) from the fuel tank (5).

b. Inspection. Inspect plug for damaged gasket or

hole cover on the heater tank cover. Secure the cover

threads. Replace plug as required.

with two wingnuts.

plug (4) on the fuel tank (5).

a. Removal.

(1) Remove fuel tank from strap cradle (para

(2) Refer to figure 5-6 and remove three wing-

a. Removal.

nuts that secure the cradle (2) to the heater.

(1) Refer to figure 5-6 and remove three wing-

b. Inspection. Inspect cradle for distorted condi-

nuts (7) holding strap (2) to heater.

tion and for missing fasteners. Replace cradle as

(2) Remove wingnut (3) securing fuel tank.

required.

(3) Lift out fuel tank (5) from holding strap.

c. Installation.

b. Cleaning and Inspection.

(1) Refer to figure 5-6 and secure the fuel tank

(1) Drain tank.

strap cradle (2) to the heater with three wingnuts.

(2) Clean outside of tank with a stiff brush and

(2) Install fuel tank and secure strap (para 5-28).

hot water.

(3) Refer to figure 5-6 and install cradle (2) on

(3) With fuel valve removed, flush fuel tank with

heater and secure with three wingnuts.

a small amount of fuel to be sure all sediment and

foreign matter are removed.

(4) Inspect tank for leaks. Replace tank as re-

quired.

valve with elbow and nipple from fuel tank (5).

c. Installation.

b. Cleaning. Scrape or scrub off any corrosion from

(1) Refer to figure 5-6 and install holding strap

valve. Clean out any obstruction from inside valve.

on heater with three wingnuts (7).

c. Inspection. Inspect fuel valve for evidence of

(2) Install fuel tank (5) onto holding strap (2).

excessive wear and leaking condition.

(3) Secure fuel tank holding strap clamp with

wingnut (3).

ple into fuel tank with elbow and fuel valve attached.

Section XII. SHIPMENT AND LIMITED STORAGE

c. Cleaning and Drying. Cleaning and drying by an

approved technique is the first essential procedure

Within Zone of Interior

in any effective preservation process. Approved

a General. Detailed instructions for the prepara-

methods of cleaning and drying, types of preserva-

tion for domestic shipment are outlined within this

tives and methods of application are described in

paragraph. Preservation will be accomplished in

TM 38-230.

sequence that will not require the operation of pre-

d. Painting. Paint surfaces where the paint has

viously preserved components.

been removed or damaged. Refer to TM 9-213 for

b. Inspection. Examine the heater for any unusual

detailed cleaning and painting instructions.

conditions such as damage or missing components.

e. Depreservation Guide. Record depreservation

Inspect the immersion heater in accordance with

instructions on DA Form 2258 or DD Form 1397 as

steps outlined in Quarterly Preventive Maintenance

applicable.

Services (para 5-18). Deficiencies and shortcomings,

f. Sealing of Openings. Openings that will permit

along with corrective action taken, will be recorded

the direct entry of water into the interior of fuel

on D-A Form 2404 (Refer to TM 38-750).