Item

No.

1

2

3

4

5

TM 5-4520-253-13

Table 2-2. Operator Preventive Maintenance Checks and Services-Continued

B—Before Operation

D—During Operation

A—After Operation

Interval

—

B

—

•

•

•

•

—

ITEM TO BE INSPECTED

PROCEDURE

Inspect the following fuel system components for leaks:

(1) Fuel inlet fitting

(2) Fuel overflow fitting

(3) Fuel lines

(4) Fuel connections

(5) Fuel overflow container

(6) Fuel supply container

(7) External fuel pump

Tighten any loose connections.

EXHAUST SYSTEM

Inspect entire exhaust system for leaks resulting from damage, cor-

rosion, and/or loose components. inspect through-the-wall installa-

tion for evidence of overheated, singed, or burned wood or other

flammable building materials. Tighten loose connection.

inspect exhaust system for fresh carbon buildup or other evidence of

exhaust leaks.

EXTERNAL ELECTRICAL CONNECTIONS

Check electrical plugs for tight seating in receptacles. Check ground

strap for secureness. Tighten loose connections.

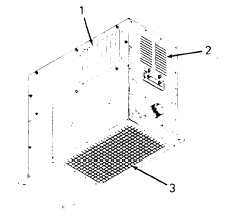

HEATER CASE

Inspect adjustable louvers (1), fixed louvers (2), and screen (3) for

obstructions. Remove obstructions.

Equipment is

Not Ready/

Available if:

Leak greater

than Class I at

fitting and any

leak in fuel line

itself or fuel

container.

Exhaust line

punctured or

rusted through.

Building material

damaged by

heat.

Exhaust line

punctured or

rusted through.

Change 1

2-2.3