TM 5-4520-253-13

lNSPECT/REMOVE/lNSTALL POWER RECEPTACLE AND EXTERNAL FUEL PUMP

- R E C E P T A C L E ( C O N T )

2. Prepare POWER RECEPTACLE (4) as follows:

a.

b.

c.

Strip 1/4 inch (6.35 mm) of insulation from cut

ends of black and white wires (5 and 6) and

ground (green) wire (7).

For Model UH-68G1, thread wires (5, 6, and 7)

through endbell (4.1) and ferrule (4.2). Thread

the stripped end of each wire through grommet

(4.3) as follows:

(1)

(2)

(3)

Slide black wire (5) through opening A of

grommet (4.3).

Slide white wire (6) through opening C of

grommet.

Slide ground (green) wire (7) through open-

ing D of grommet.

Solder wires (5, 6, and 7) to receptacle termi-

nals as follows:

(1) Black wire (5) to terminal A.

(2) White wire (6) to terminal C.

(3) Ground (green) wire (7) to terminal D.

For Model UH-68G, pot wires as described in

step 3, following.

For Model UH-68G1, push grommet (4.3) into

rear of receptacle (4), ‘seat ferrule (4.2) over

grommet, and tighten endbell (4.1) to threads

on rear of receptacle.

3. For Model UH-68G, the procedure for potting wires to POWER RECEPTACLE and EXTERNAL FUEL

RECEPTACLE is the same for both receptacles. Proceed as follows:

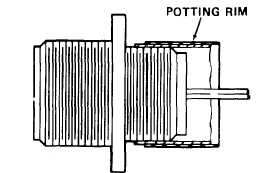

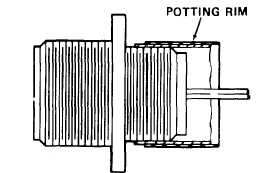

a. Make potting rim around receptacle using tape.

Rim must project beyond receptacle around

wires 1/4 inch (6.35 mm) or more.

b. Fill rim with sealant and allow 8 hours to cure.

4. Install EXTERNAL FUEL PUMP RECEPTACLE (11) inmounting hole from inside heater case. Secure recep-

tacle using four screws (8), lock washers (9), and nuts (10). Attach terminal end of ground wire (14) to one

screw/lock washer/nut combination during this step.

Change 2

3-63

d .

e.