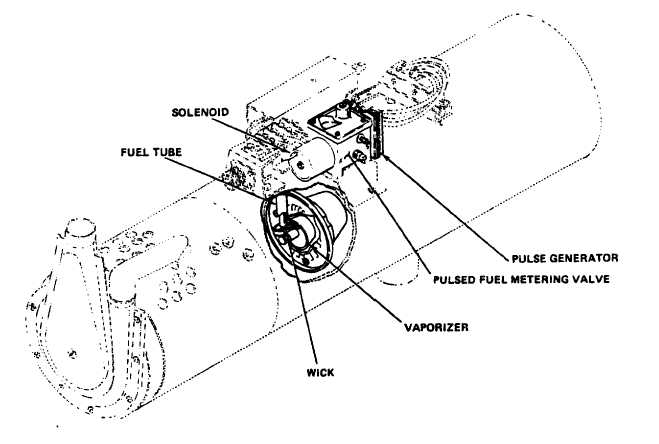

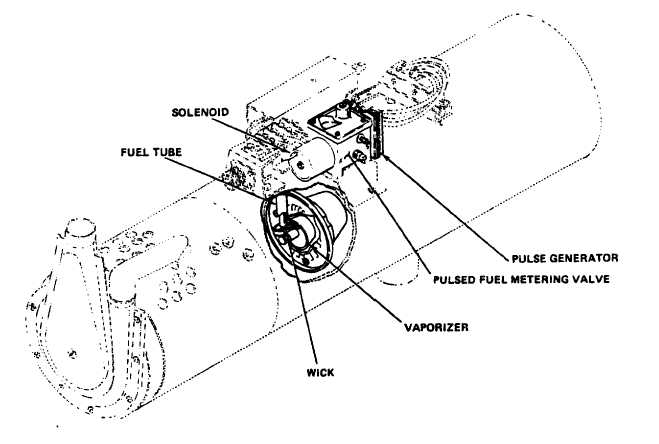

FUEL SYSTEM

Stewart-Warner 10560M24B1, 10560M

PULSED FUEL METERING VALVE-Controls pressure, temperature, and delivery of incoming fuel. Pressure

is regulated by a needle valve and diaphragm. Fuel is heated by an electronic heater, and fuel temperature is

monitored by a snap-action thermostat. Fuel is metered by passing through a calibrated orfice.

Rate of fuel flow through fuel metering valve is determined by the number of pulses generated for a specific

period by the pulse generator. These pulses are sent to the solenoid plunger, causing it to open and allowing

the fuel to flow.

SOLENOID-Turns fuel flow on and off. Controlled by pulse generator.

PULSE GENERATOR-Determines operating frequency of solenoid. Adjustable for both HI and LO heat op-

eration. Controlled by switch settings on control box.

FUEL TUBE-Rigid tube used to deliver fuel to heater.

VAPORIZER-Spreads fuel over a large surface area for better mixing with air before burning.

WICK-Presents fuel/air mixture to igniter for lighting.

1-17

TM 9-2540-205-24&P