TM 10-4500-200-13

S e c t i o n X. TROUBLESHOOTING

4-24. General

occur are listed in table 4-2. Each malfunction stated

is followed by a list of probable causes of trouble. The

corrective action recommended is described opposite

and correcting unsatisfactory operation or failure of

the probable cause.

the immersion heater. Malfunctions which may

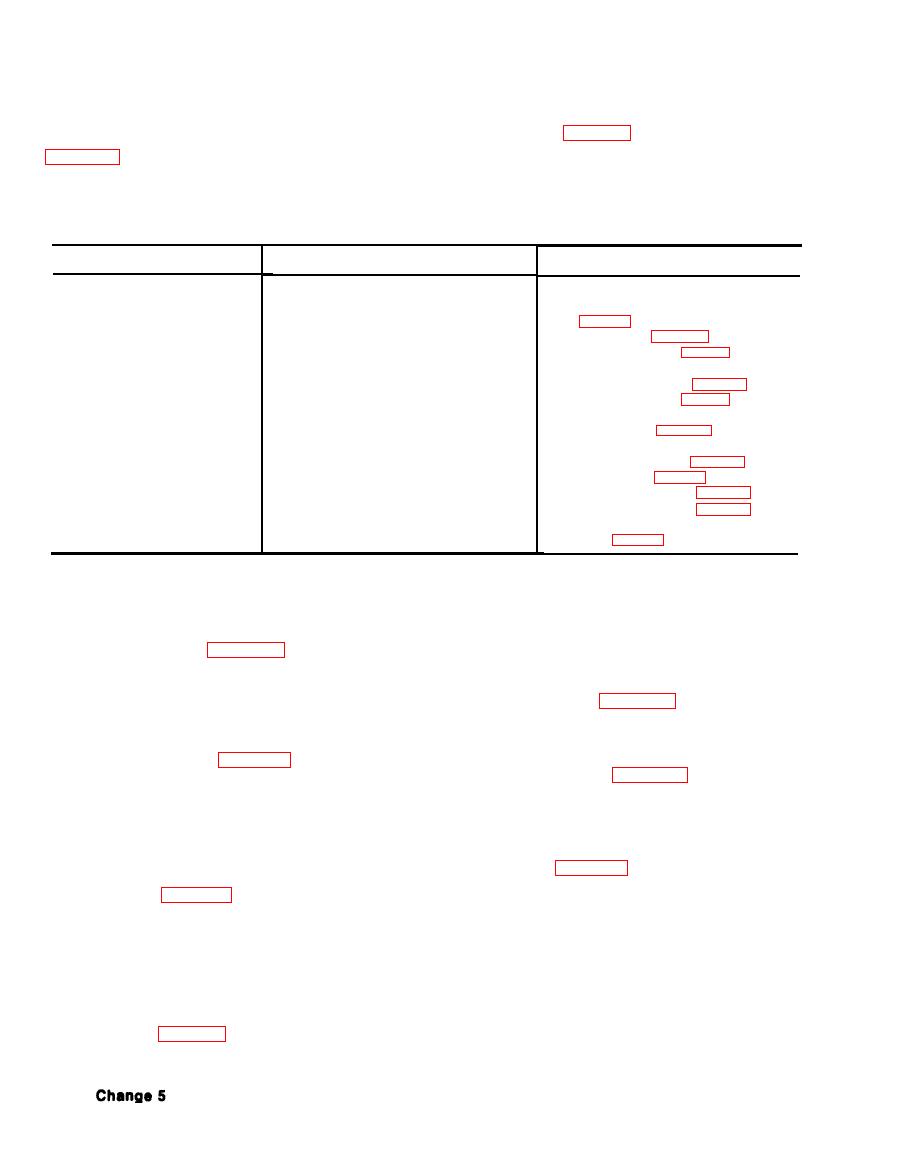

Table 4-2. Troubleshooting

Malfuntion

Probable cause

Corrective action

1. Heater fails to start

a. Insufficient preheating of flue

Repeat preheating. Leave lighter in flue

compartment until heater starts

b. Vent plug closed

Open vent plug (para 4-11)

c. Fuel tank empty

Remove and fill tank (para 4-1)

d. Water present in combustion

Stop operation and clear water from

chamber

combustion chamber (para 4-15).

2. Burner goes out

a. Fuel tank empty

Remove and fill tank (para 4-1)

b. Vent plug closed or clogged

Open vent plug and be sure it is free

of obstruction (para 4-11}

c. Water present in combustion

Stop operation and clear water from

chamber

combustion chamber (para 4-15).

d. Fuel rate too slow

Open fuel valve (para 4-11)

e. Flame blown out

Close fuel valve slightly (para 4-13)

3. Heater smokes

a. Fuel rate too fast

Close fuel valve slightly (para 4-13)

b. Stack is too short

Be sure to use at least four sections

of pipe (para 4-6).

Section XI. ORGANIZATIONAL MAINTENANCE PROCEDURES

(2) Insert the hinge pin (11), and secure it with

the cotter pin (13).

draft gate supporting screw (20), the draft gate screw

nut (21), and the draft gate (22) from the heater.

b. Inspection. Inspect the draft gate for a warped,

filler plug (4) from the fuel tank (2).

distorted condition. Replace the draft gate as

b. Inspection. Inspect the plug for a damaged

required.

gasket or threads. Replace the plug as required.

gate (22) on the heater body, and secure it with the

filler plug (4) on the fuel tank (2).

draft gate supporting screw (20) and the draft gate

screw nut (21).

a. Removal.

4-26. Hood

(1) Refer to figure 4-6, and remove the wingnut

a. Removal.

(5) that secures the hinged fuel tank strap.

(1) Refer to figure 4-6, and remove the cotter pin

(2) Open the strap and remove the fuel tank (2)

(2) Remove the hinge pin (11) and lift off the hood

from the fuel tank cradle (6).

(12) from the burner collar (21).

b. Cleaning.

(1) Drain the tank.

b. Inspection. Inspect the hood for a distorted

(2) Clean the outside of the tank with a stiff

condition/broken hinge. Replace the draft gate as

brush and hot water.

required.

(3) With the fuel valve removed, flush the fuel

c. Installation.

tank with a small amount of fuel to be sure al'

(1) Refer to figure 4-6, and place the hood (12) on

sediment and foreign matter are removed.

the burner collar (23).