TM 9-4520-272-14&P

OPERATOR, FIELD AND SUSTAINMENT MAINTENANCE

LARGE CAPACITY FIELD HEATER (LCFH)

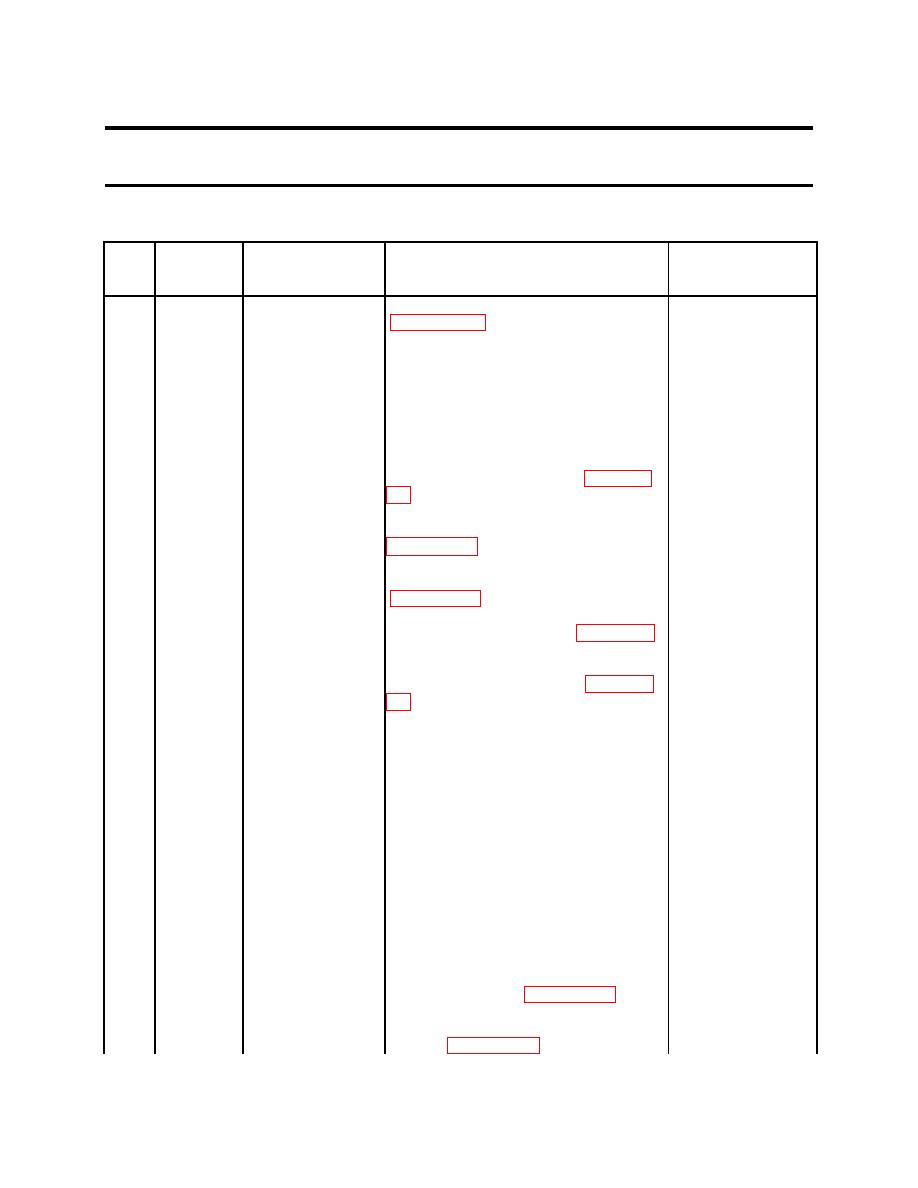

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Table 1. Unit Preventive Maintenance Checks and Services.

ITEM

INTERVAL LOCATION/ITEM

PROCEDURE

NOT FULLY

NO.

TO

MISSION CAPABLE

CHECK/SERVICE

IF:

1

100

Engine oil strainer

Remove and clean engine oil strainer

Oil strainer is

hours

clogged, dirty, or

damaged.

2

250

Engine lubricating

Engine oil has not

NOTE

hours

oil system

been changed.

First oil service occurs between 20

and 50 hours of operation, 250

hour intervals thereafter.

Service engine lubricating oil (WP 0046

3

Check

Burner nozzle and

Check burner nozzle and electrodes IAW Burner nozzle

every 250

electrodes

clogged or

hours;

electrodes out of

replace at

Replace burner nozzle at 1000 hours

adjustment.

1000 hours

4

250

Heat Exchanger

Drain heat exchanger IAW WP 0054.

Heat exchanger

hours

retaining fluid.

5

500

Engine air filter

Remove and replace air filter (WP 0046

Air filter is dirty or

hours

damaged.

6

500

Diesel engine

a. Inspect fuel injection pump for

Fuel leak of any kind

hours

injection pump

damage and evidence of leakage.

is present.

b. Check area around pump sealing

gasket for leaks. Remove and replace

gasket as required (refer to Direct

Support Maintenance).

7

500

Engine intake and

Valves are not

NOTE

hours

exhaust valve

properly adjusted,

clearance

causing improper

First valve clearance check occurs

engine operation.

between 20 and 50 hours of operation,

500 hour intervals thereafter.

Adjust valve clearance of intake and

exhaust valve seats (WP 0041 00).

8

500

Diesel engine

Inspect fuel injector nozzle, replace as

Fuel injector nozzle

hours

injection nozzle

required (WP 0043 00).

clogged or otherwise

0018 00-1