TM 9-4520-272-14&P

0016 00

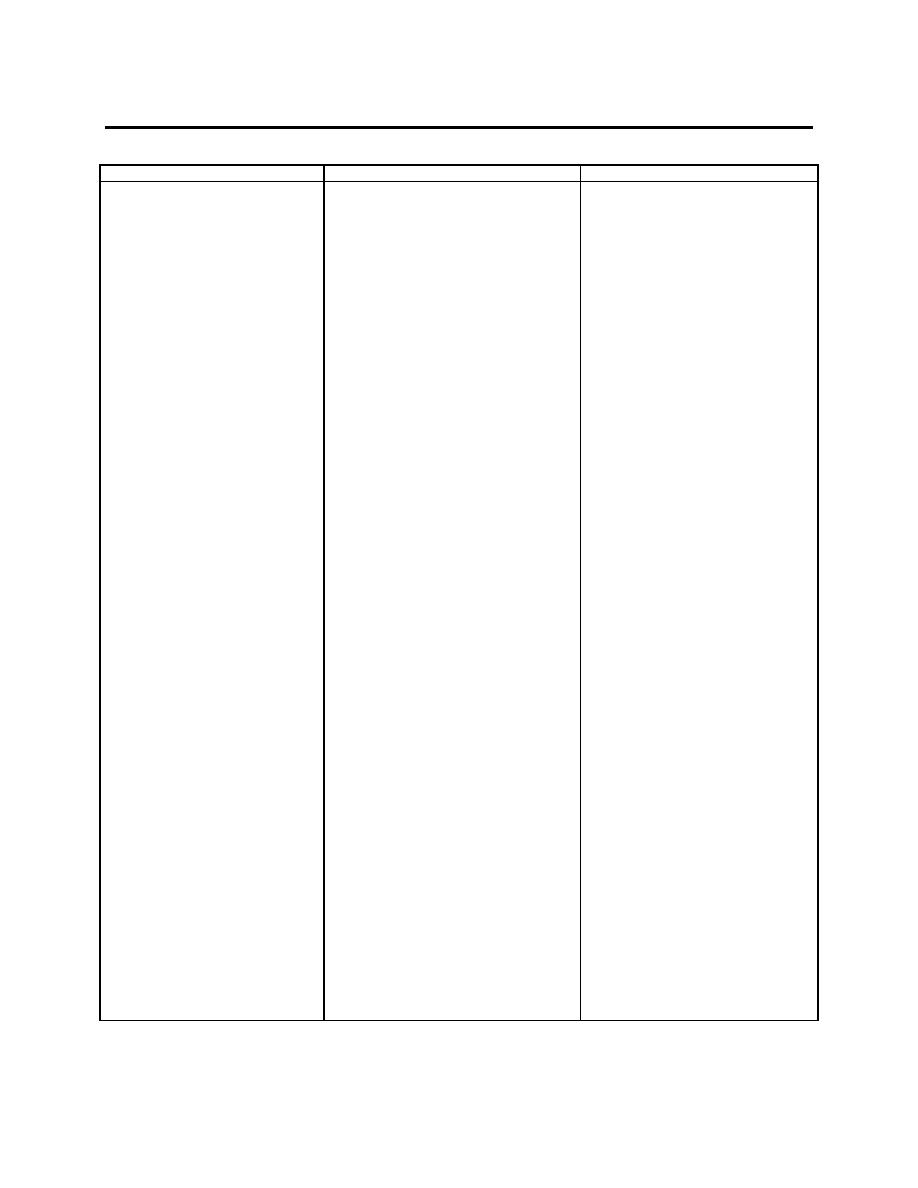

Table 1. Troubleshooting Procedure for Large Capacity Field Heater (LCFH).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

getting into the LCFH airflow.

there is no evidence of high carbon

monoxide levels, replace the

operator control panel carbon

monoxide detector.

Step 1. Repair any tears in the

55. Heater starts, shuts down,

Step 1. This fault code indicates that the

and displays fault code: H312

flexible air inlet duct with duct tape.

LCFH has detected carbon monoxide at

Replace flexible air duct if damage

the cabinet mounted carbon monoxide

cannot be completely repaired with

detector. Evacuate any personnel that

duct tape.

may be in the shelter and look for signs

of carbon monoxide poisoning. Check

the flexible air inlet duct and ensure that

it does not have any rips, tears, or other

damage that would allow combustion

exhaust to enter the inlet air flow.

Step 2. Re-attach flexible air inlet

Step 2. Check and ensure that the

duct to air inlet duct adapter lock in

flexible inlet air duct is securely

place securely.

attached to the air inlet duct adapter on

the LCFH.

Step 3. Move LCFH so that

Step 3. Ensure that the shelter opening

combustion exhaust does not enter

is not downwind of the LCFH is such a

shelter during LCFH operation.

way as to allow combustion exhaust to

enter the shelter.

Step 4. Restart LCFH. If fault

Step 4. Determine if there are any other

reoccurs, stop use of LCFH and

sources of carbon monoxide (vehicles,

notify Unit Maintenance.

generators, etc.) that may be running

nearby. Determine if the combustion

Step 5. Step 5. If problem reoccurs

exhaust from those sources may be

and there is no evidence of high

getting into the LCFH airflow.

carbon monoxide levels, replace the

cabinet mounted carbon monoxide

detector.

56. Fuel leak is observed in the

Step 1. Determine the area where the

Step 1. Shut down heater. If fuel leak

heater.

leak is originating. In all likelihood, this

has been detected in a flare titting,

will be in the area of the fuel panel

re-tighten. If fitting continues to leak,

assembly, the burner valve assembly,

inspect for dirt or debris on the flare

or the fuel tank assembly.

"male" and "female" areas and clean

if needed. If leak persists, replace

both hose and component.

Step 2. For fuel leaks in hoses using

barb fittings and screw hose clamps,

ensure that the hose is fully inserted

onto the hose barb and then re-

tighten the clamp.

Step 3. If a leak is found anywhere in

the length of the hose, replace entire

hose.

END OF WORK PACKAGE

0016 00-16