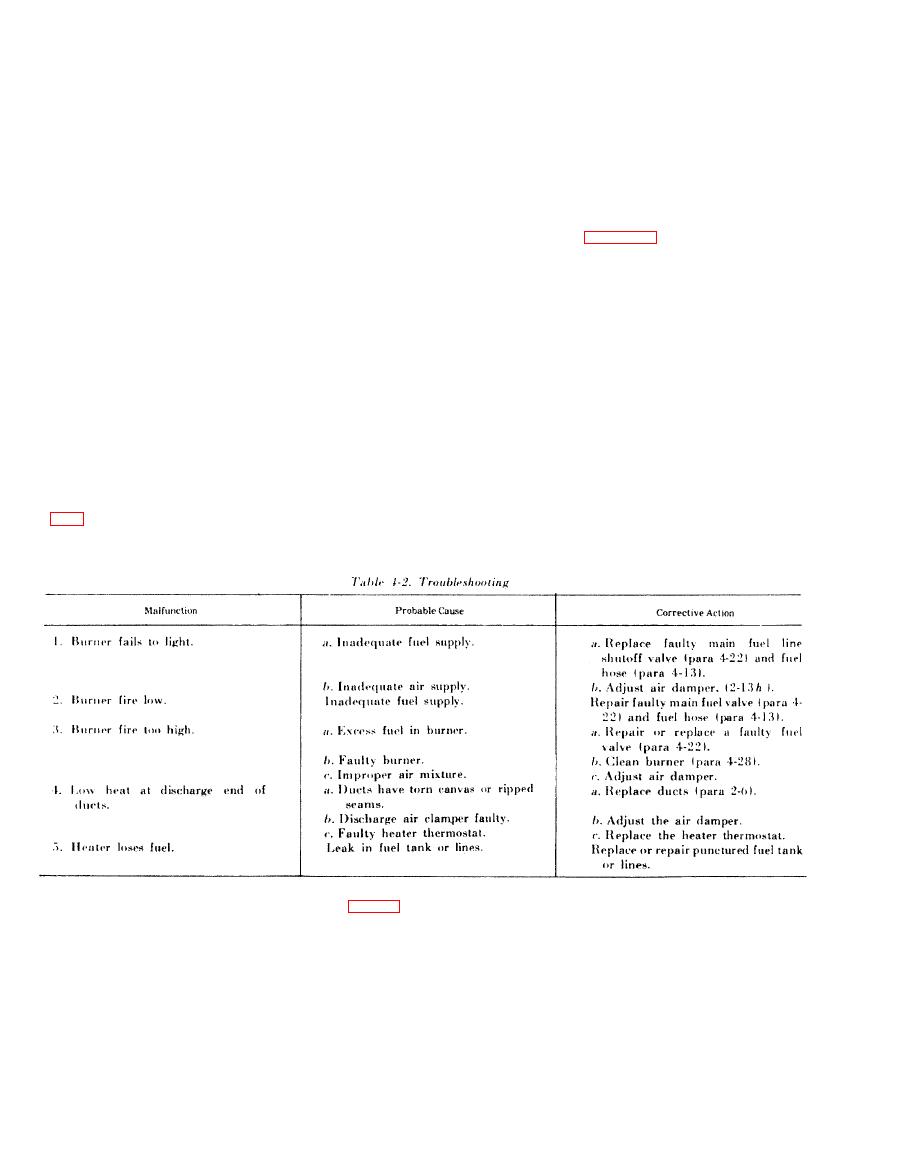

Section VI. TROUBLESHOOTING

the defective component. Do not overlook the

General

importance of questioning the operator to get as

This section contains troubleshooting information

many definite symptoms as possible.

in tabular form to help in locating and correcting

s o m e of the common troubles which may develop in

Troubleshooting

Procedures

the heater. This section cannot cover all of the

Malfunctions and troubleshooting procedures for

troubles or malfunctions that may occur. If a

t h e engine assembly are shown in TM5-2805-256-

s p e c i f i c m a l f u n c t i o n o r t h e t r o u b l e s h o o t i n g in-

14. Malfunctions and troubleshooting for the

s t r u c t i o n is not covered in these charts, isolate the

heater are listed in table 4-2.

s y s t e m in which the trouble occurs and then locate

Section VII. RADIO INTERFERENCE SUPPRESSION

Radio interference suppression components

are

described in TM5-2805-256-14.

Section VlIl. MAINTENANCE OF THE ENGINE ASSEMBLY

remove the flexible fuel line at the engine fuel

pump.

a.

Removal.

(3) Remove the two screws holding the

(1) Close the main fuel line shutoff valve (fig.

flexible line housing clamp to the blower wheel

housing.

(2)

Unscrew

the

flexible

line

coupling

and

(4) Remove the self-locking nuts (1, fig. 4-1)

( 8 ) Remove the engine and the mounting base

which hold the fan guard (6) to the heater.

b y sliding off the track.

( 9 ) Remove the nuts, bolts, flat washers, and

(5) Remove the bolts which hold the engine

m o u n t i n g base

to

the

left

and

right

engine

lockwashers securing the engine to the engine

mounting brackets.

mounting base, and remove the engine from the

( 6 ) Remove the nuts which are located on the

base.

blower wheel housing duct.

b. Inspection. Check the engine assembly for

(7) Loosen the fan guard from the studs.

cracks, breaks, distortions, and any other visible

defects. If it is defective, replace it as authorized.