TM 5-4520-208-15

c. Flow Test.

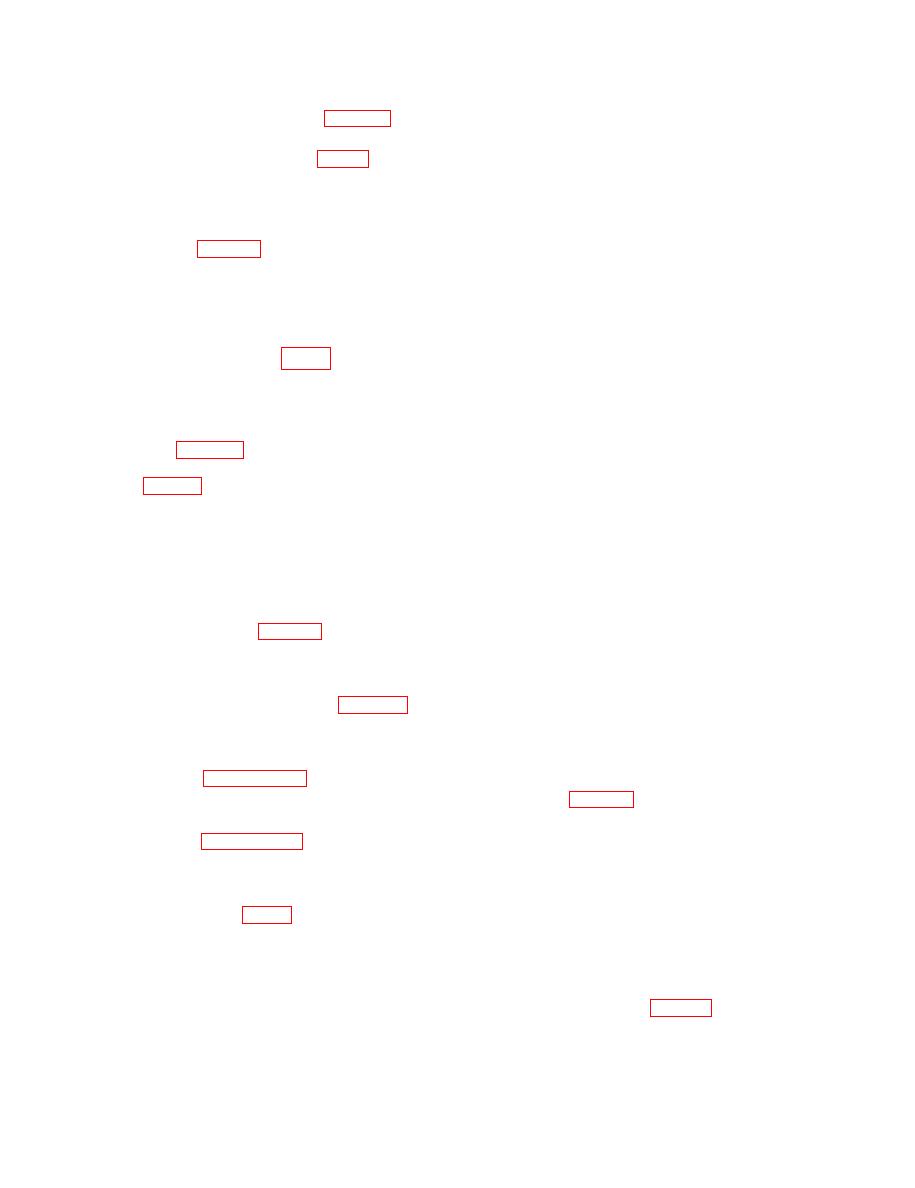

Disconnect pump-to-coupling tube as-

sembly (54) at coupling (56).

(1) Remove the power unit (para 12).

(4) Remove two screws (58) and flat

(2) Disconnect fuel pump-to-fuel tank by-

washers (57) securing fuel pump as-

pass tube assembly (4, fig. 33) from

sembly (52 ) to bracket. Remove fuel

fuel tank. Disconnect tube assembly

pump, with attached tube assemblies,

entering fuel tank adjacent to fuel

from heater.

cap. Connect a flexible tube or hose

(5) Disconnect tube and hose assemblies

to fuel tube assemblies. Install pow-

(48, 50, 54, and 55) from fuel pump.

er unit (para 12).

Remove three pipe elbows (49 and 51)

(3) obtain two liquid containers, each hav-

from fuel pump. Remove straight

ing at least a one gallon capacity.

adapter (53 ) from fuel pump.

Place hose or flexible tubes leading

(6) Remove setscrew (36) and remove fuel

from tube assemblies in unmarked

pump groove pulley (35) from fuel

container.

pump.

(4) Close the damper (fig. 13) by loosen-

ing and moving handwheel all the

e. Cleaning and Inspection.

way to the left (when facing discharge

(1) Clean all parts in an approved clean-

end).

ing solvent and dry thoroughly.

(5) Set the temperature selector indicator

(2) Inspect all parts for evidence of leak-

knob (fig. 11) for a discharge air tem-

ing, breaks, cracks, damaged threads,

perature of 150F. Start the heater

restriction of movement, or other dam-

age. Replace all damaged parts.

lector indicator knob as necessary until

f. Installation.

discharge air temperature is stable at

(1) Position fuel pump groove pulley (35)

150F.

on fuel pump shaft and secure with

(6) When the temperature is stable, trans-

setscrew (36).

fer the hose or flexible tubes to the

(2) Install straight adapter (53) in fuel

measuring container. Record the time

pump assembly (52). Install three pipe

necessary for a flow of one gallon.

elbows (49 and 51) in fuel pump.

Stop the heater (para 33).

(3) Connect tube and hose assemblies (48,

(7) If the time required to measure one

50, 54, and 55) in elbows and con-

gallon of flow is more than five

nector.

minutes, replace the fuel pump.

(8) Remove the power unit (para 12).

(4) Position fuel pump assembly (52),

Disconnect hose or flexible tubes from

with attached tube assemblies, on

fuel lines and connect tube assemblies

mounting bracket. Secure fuel pump

to fuel tank.

with two screws (58) and flat washers

(9) Refer to paragraph 12 and install the

(57). Install V-belt and adjust V-belt

power unit.

tension (para 47).

(5) Connect fuel pump-to-coupling tube

d. Removal.

assembly (54) to coupling (56). Con-

(1) Refer to paragraph 12 and remove the

nect fuel pump-to-casing tube assem-

power unit. Remove V-belt from pul-

bly (55) to flexible elbow (62) at

leys.

side of casing.

(2) Disconnect filter-to-pump metal hose

(6) Connect pump-to-tank tube assembly

assembly (50, fig. 34) from fluid filter

(48) to straight adapter (34) at fuel

(47). Disconnect pump-to-tank tube

tank. Connect fuel filter-to-pump met-

assembly (48) from straight adapter

al hose assembly (50) to fluid filter

(34) at tank.

(47).

(3) Disconnect fuel pump-to-casing tube

assembly (55) at flexible elbow (62).

(7) Install power unit (para 12).

54