TM 5-4520-208-15

with no outlet for the air and possible damage

from a heat buildup within the heater.

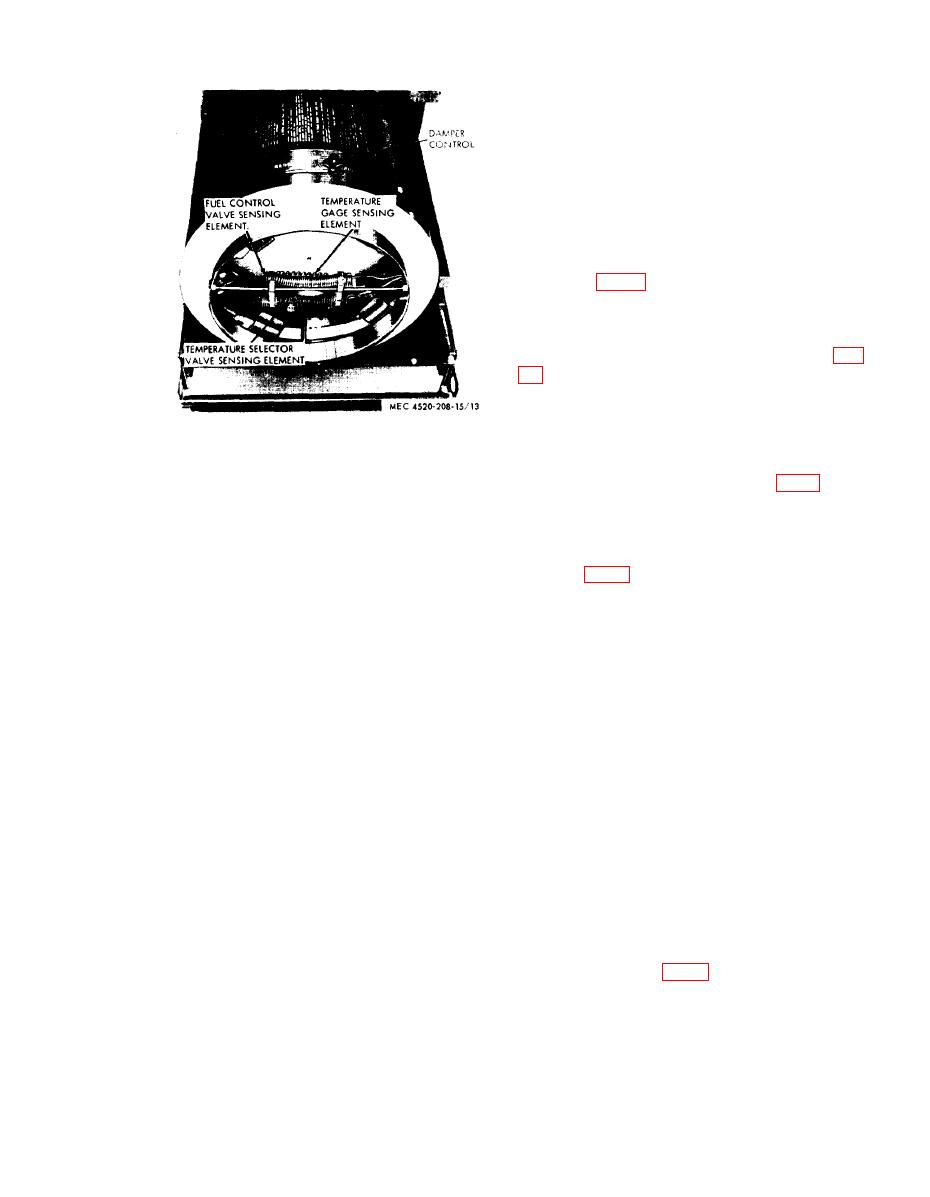

30. Sensing Elements

a. General. Three sensing elements are

mounted in front of the damper in the dis-

charge end of the heater. The elements are

directly in the air stream so the temperature of

the air directly affects the elements.

b. Discharge Air Temperature Gage Sensing

temperature to the temperature gage! mounted

in the control box. The temperature gage reg-

isters the temperature in degrees Fahrenheit.

c. Fuel Control Valve Sensing Element (fig.

in the fuel control valve. When the discharge

air temperature exceeds safe limits (about 350

F) the gas in the element will expand enough

to force the diaphragm up and open the fuel

Figure 13. Heater discharge air controls.

control valve. Opening the fuel control valve

opens the primary bypass line (fig. 3) and

heater. The control handwheel is mounted on

reduces the outlet pressure at the fuel pump.

the top of the casing.

The drop in pressure makes it impossible for

b. The damper control, attached to the damp-

the nozzle to receive fuel, stopping combustion.

er, is secured by the handwheel, To move the

d. Temperature Selector Valve Sensing

damper control, loosen the handwheel.

Element (fig. 13). Gas in the temperature se-

lector valve sensing element controls a dia-

c. Moving the damper control as far as pos-

phragm in the temperature selector valve. As

sible to the left (when facing discharge end)

the discharge air reaches the selected tempera-

completely closes the damper. As the damper

ture, the gas expands and, through action of

control is moved to the right the damper opens

the diaphragm, opens the temperature selector

increasing the volume of discharge air leaving

valve, decreasing the nozzle fuel flow. The

the heater. The damper controls the volume

action of the temperature selector valve will

from fuel to one-half the rated flow. The dis-

maintain the selected temperature by increasing

charge air outlet cannot be completely closed,

or decreasing fuel flow through the nozzle.

preventing accidental operation of the heater

Section IV. OPERATION OF EQUIPMENT

represents a different problem, the operator

31. General

may have to vary given procedures to fit the

a. The instructions in this section are pub-

individual job.

lished for the information of the personnel

responsible for operation of the BT400-40 and

32. Starting

BT400-40-1 heaters.

a. Preparation for Starting.

b. The operator must know how to perform

every operation of which the heater is capable.

(1) On Model BT400-40 heaters, remove

cabinet (fig. 1) by disengaging

This section gives instructions on starting and

latches.

stopping the heater. Since' nearly every job

21