TM 5-4520-208-15

b. Turning the temperature selector valve

indicate E (empty), 1/4, 1/2, 3/4, and F

knob clockwise increases the discharge air tem-

(full).

perature; turning it counterclockwise decreases

27. Time Totalizing Meter (BT400-40)

the temperature.

mounted above the magneto. A rubber belt

22. Choke Control

(preformed packing) drives a pulley attached

to the time totalizing meter shaft. The belt is

cated on the carburetor. It enables the operator

driven by the magneto pulley.

to enrich the fuel mixture for cold weather

b. The time totalizing meter is direct read-

starting.

ing and records the heater operating time in

b. The control is an external lever which

hours.

can be held in any desired position. When the

lever is rotated fully counterclockwise the valve

28. Electric Motor Power Unit On-Off

is closed and the gas mixture is enriched.

Switch

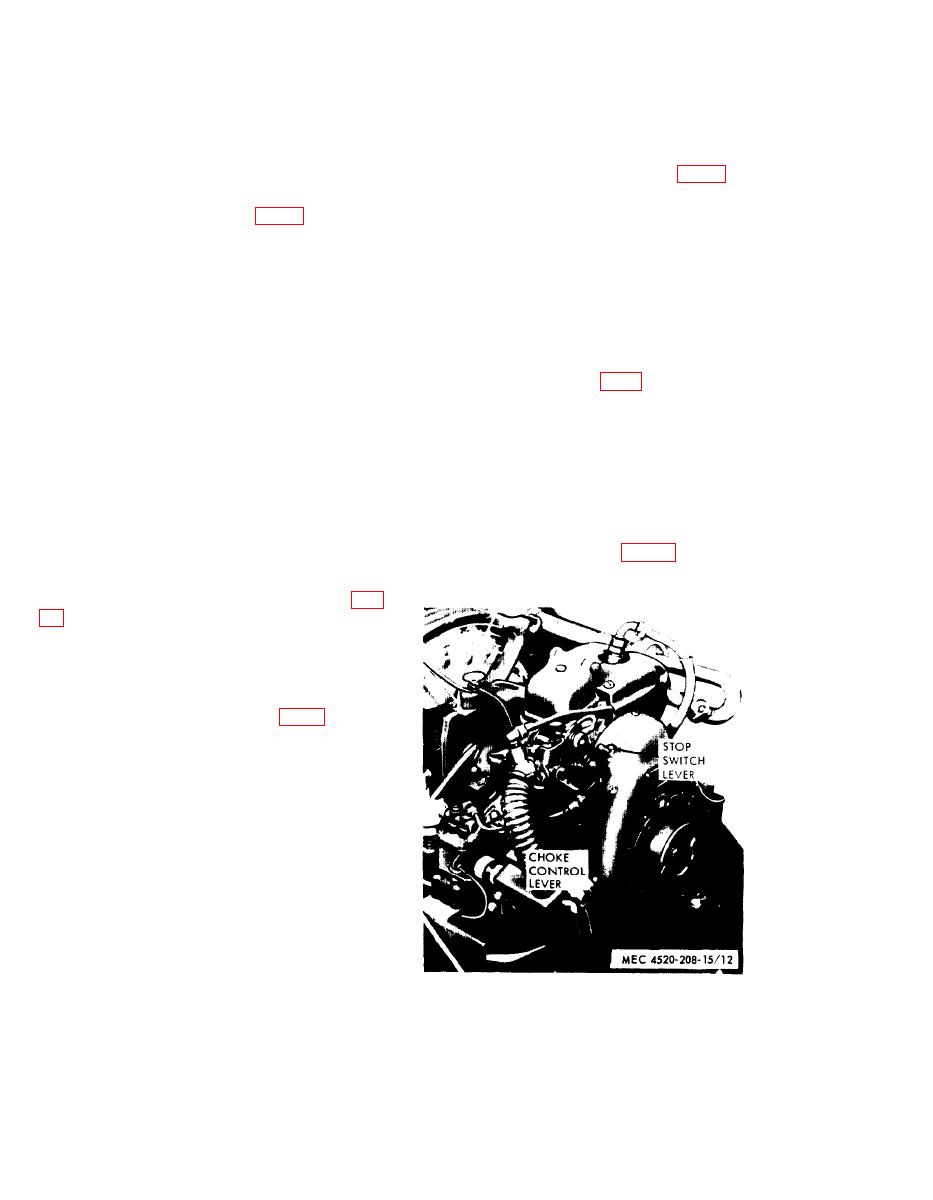

23. Stop Switch Lever

eration of the electric motor power unit. The

a. The stop switch lever (fig, 12) is mounted

ON-OFF switch is mounted on the electric

on the top of the flywheel housing.

motor power unit junction box.

b. To stop the engine power unit, set switch

b. The ON-OFF switch is a two-position, tog-

lever to OFF position.

gle type switch and is used to start and stop

the motor.

24. Starting Rope

a. The starting rope is furnished for the pur-

29. Damper Control

pose of manually cranking the engine power

unit.

a rotating damper at the discharge end of the

b. Engage the rope in the flywheel flange

and pull rope to start the power unit (fig.

25. Fuel and Exhaust Controls

a. The engine hose assembly leading from

the fuel tank is a flexible hose' equipped with

a quick-disconnect coupling (fig. 7). Push

coupling away from fuel filter to disconnect

hose assembly.

b. An exhaust extension leading from the

manifold has a flange near the end. The ex-

haust extension is inserted into the exhaust

pipe and the flange bears on a mating flange

on the exhaust pipe under spring pressure to

provide a gastight fitting.

26. Fuel Gage

a. The fuel gage is mounted beneath the

heat exchanger on the right side of the base.

The fuel tank cap is next to the gage.

b. The fuel gage is a needle-indicating type,

direct reading gage. Graduations on the gage

Figure 12. Gasoline engine power unit controls.

20