TM 5-4520-208-15

tached, in bore of plate. Secure nozzle

plug electrode (3).

holder by engaging clamp (3) in

notches on combustor.

(2) Install the plate (4, fig. 31) on com-

(5) Insert ignition cable (7) through hole

bustor (2).

in casing, and secure grommet (6)

(3) On Model BT400-40 heaters, insert

around cable. Connect ignition cable

nozzle holder (1) in bore of plate,

to igniter plug (5) and magneto (9).

tighten tube assembly fittings, and in-

(6) Refer to paragraph 77 and install the

stall clamp (3) in notches on cornbus-

mounting ring.

tor to secure nozzle.

(4) On Model BT400-40-1 heaters, insert

(7) Refer to paragraph 12 and install the

nozzle holder (1), with clamp at-

power unit.

Section XII. HEATER FUEL SYSTEM (BT400-40)

84. General

The heater fuel system consists or a fuel

tank mounted in the base, fuel filter, tube as-

semblies, fuel pump, fuel control box, and

combustor.

85. Fuel Pump and Heater Fuel Tube

Assemblies

a. General The fuel pump is mounted on a

bracket to the left of the nozzle. The pump is

belt-driven by the power unit. A flexible hose

assembly delivers fuel, through the fuel filter,

to the fuel pump. During the heating cycle

fuel travels from the nozzle and secondary

bypass line. Bypass fuel is returned to the fuel

tank from the nozzle and secondary bypass

line.

b. Pressure Test and Adjustment.

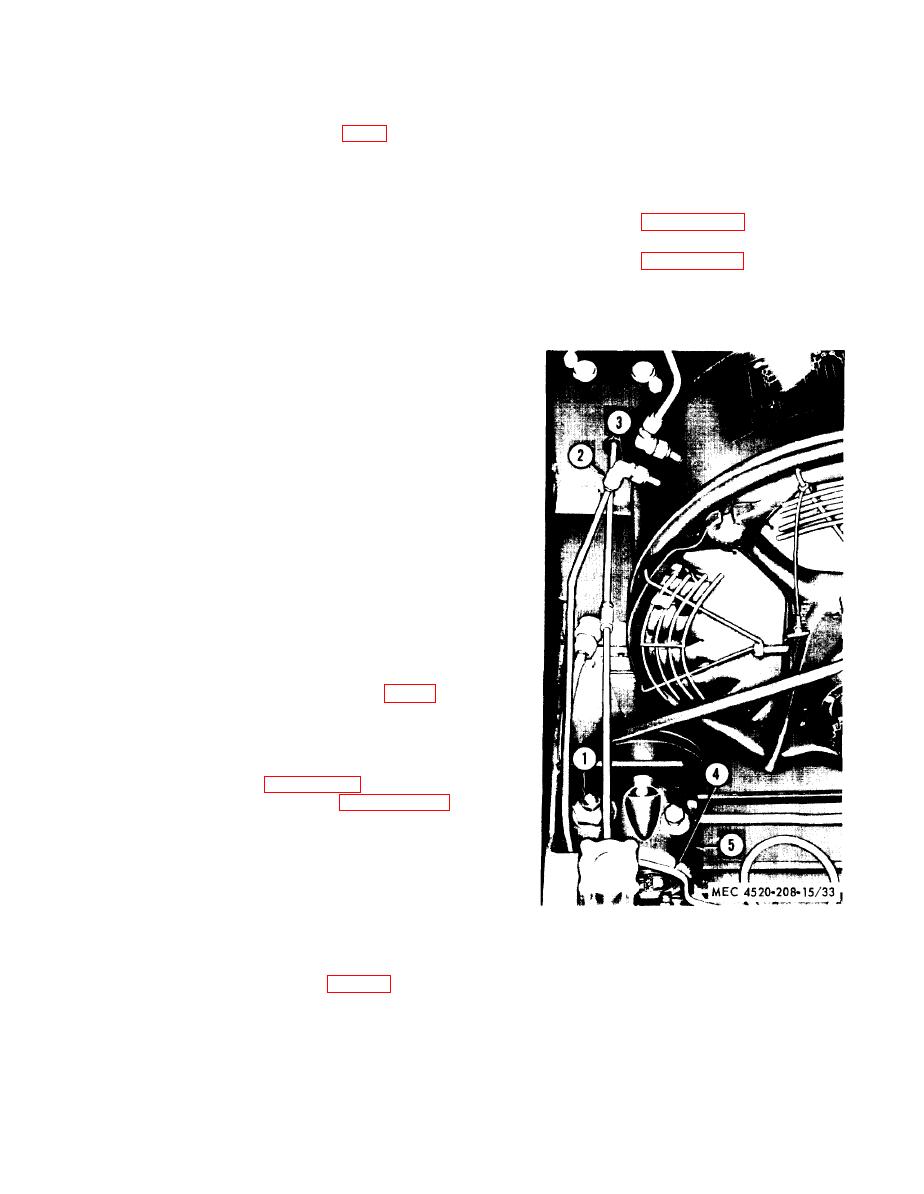

(1) Disconnect fuel pump-b-nozzle pres-

sure tube assembly (2, fig. 33) from

elbow (3).

(2) Using an adapter, connect a pressure

gage with a maximum reading 200

psi in pressure tube assembly (2).

(3) Refer to paragraph 12 and install pow-

er unit. Refer to paragraph 32 and

start the heater and observe pressure

gage reading. The pump should be

operating at 150 psi, plus or minus 2

psi.

(4) If the reading is not within operating

pressure tolerance, remove nut (1) and

1

Nut

turn ajusting screw clockwise to in-

2

Pressure tube assembly

crease the pressure, or counterclock-

Elbow

3

wise to decrease pressure.

4

Bypass tube assembly

5

Fuel pump

(5) Stop the heater (para 33). Remove the

pressure gage and connect the pres-

Figure 33. Fuel pump, pressure test points

sure tube assembly (2).

(BT400-40).

53