TM 9-4520-257-12&P 0002 00

0002 00-4

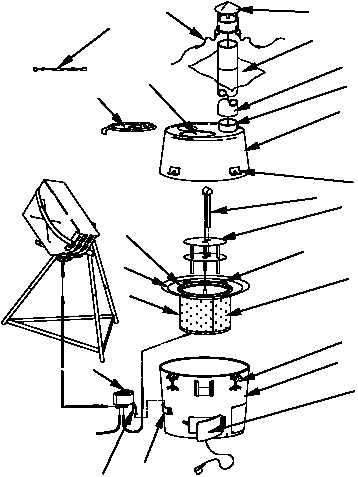

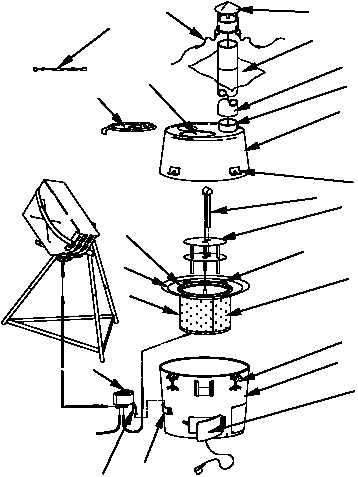

Burner shell assembly and adapter ring. The burner shell assembly (3) fits into the heater body

base (1). It consists of a rolled steel pot (13) with a high fire ring (14), a burner cap assembly (15), and a

superheater assembly (16). An adapter ring (17) that engages the upper rim of the heater body base (1) is

welded to the burner shell assembly (3). The high fire ring (14) is held in place by three clamps (18) that

attach to the adapter ring (17) with pan head screws. A cleaning tool (19) is used to clean soot and any

buildup from the inside of the up-tube and down-tube.

Fuel flow control valve. The fuel flow control valve (20) is mounted on the side of the heater body base

(1). The fuel flow control valve (20) is designed to function with JP-8; DF-A, DF-1, or DF-2; JP-5;

kerosene; Jet A-1; Jet A; gasoline (emergency only); and JP-4 (emergency only). It has several orifices

to match the various viscosities of the fuels being used. The orifices are cut to permit a maximum and

minimum flow rate consistent with the safe operation of the heater.

Exhaust system. The exhaust system consists of six stack-pipe sections (12) connected end to end,

leading from the 4-inch (10.16-cm) externally flanged circular cutout (11) on the top heater shell (2),

through the tent roof (21), and topped by a stack cap assembly (22), to which three wire ropes and guy

lines (23) are attached to provide stability.

Hose assemblies. The hose assemblies conduct fuel from the fuel source to the fuel flow control valve

(20), from the fuel flow control valve (20) to the burner shell assembly (3), and from the fuel flow control

valve (20) to the overflow area.

2

8

11

12

15 16

3

17

14

13

18

5

6

20

21

22

9

10

19

1

4

7

23

Major Components of the H-45 Type II (Liquid Fuel) Heater