TM 10-4500-200-13

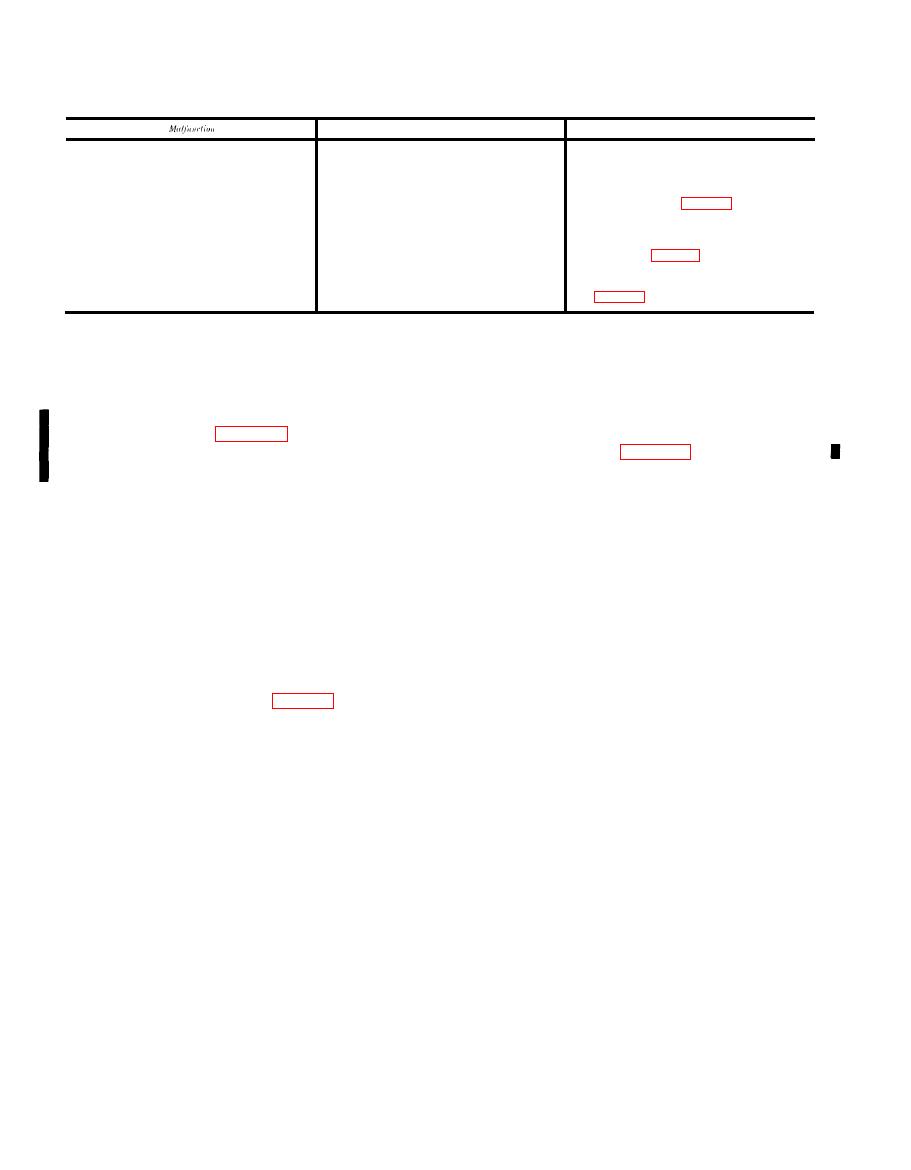

Table 2-2. Troubleshooting (continued)

Corrective action

Probable cause

a. Adjust valve level by eye, a level is not

4. Any flow of fuel from overflow hose,

a. Valve too far out of level to operate

necessary.

properly.

b. Remove valve. Takle outside tent, clean

b. Dirt under inlet float needle seat.

strainer and flush out valve. Do not

disassemble valve (para 2-31).

c. Remove valve and take outside tint.

c. Float sticks at time.

Remove valve cover and check movement

of float pivot mechanism. Replace valve

if defective (para 2-31).

d. Remove cover and check float. If float

d. Defecive float in valve.

has any liquid in it, replace valve

Section XI. ORGANIZATIONAL MAINTENANCE PROCEDURES

guy lines from cotton cord, allowing 15 feet of cord for each

2-37. Guy Lines

line.

lines from the flue cap.

lines to the flue cap.

b. Repair. Replace guy lines as required. Manufacture

Section XII. SHIPMENT AND LIMITED STORAGE

f. Exterior Surfaces. Coat exposed ferrous metal sur-

faces with type P-6 preservative (CL) conforming to Speci-

within Zone of Interior

a. General. Detailed instructions for the preparation

fication MIL-C-11796, Class 3. If the preservative is not

available, use Automotive and Artillery Grease (GAA).

for domestic shipment ar outlined within this paragraph.

g. Marking. Mark in accordance with MIL-STD-129.

Preservation will be accomplished in sequence that will not

require the operation of previously preserved components.

b. Inspection. Examine the item for any unusual condi-

a. General. This paragraph provides instructions for

tions such as damage or missing components. Inspect the

preparation of the space heater for limited storage, not to

space heater in accordance with steps outlined in Quarterly

exceed six months.

Preventive Maintenance Services (table 2-1). Deficiencies

b. Inspection and Maintenance of Equipment in Stor-

and shortcomings along with corrective action taken, will

age. When space heaters have been placed in limited stor-

be recorded on DA Form 2404 (Refer to DA PAM 738-750).

age, all scheduled preventive maintenance services, includ-

c. Cleaning and Drying. Cleaning and drying by an

ing inspection, shall be suspended and preventive

approved technique is the first essential procedure in any

maintenance inspection shall be performed as specified

effective preservation process. Approved methods of clean-

herein. Perform quarterly preventive maintenance services

ing and drying, types of preservatives, and methods of

when the space heater is initially placed in limited storage

application are described in TM 38-230.

Guide. Record

depreservation

and every 90 days thereafter. Record all deficiencies and

d. Depreservation

shortcomings, together with corrective action taken, on DA

instructions on DA Form 2258 or DD Form 1397 as applica-

Form 2404. Required maintenance will. be performed

ble,

promptly to insure that the space heater is mechanically

e. Sealing of Openings. Openings that will permit the

sound and ready for immediate use.

direct entry of water into the interior of fuel lines, oil

burners, fittings, and float valves, shall be sealed with

pressure-sensitive tape conforming to Specification PPP-T-

60, Class 1, or covered with waterproof kraft wrapping

paper (UU-P-271) secured in place with tape.

Change 14