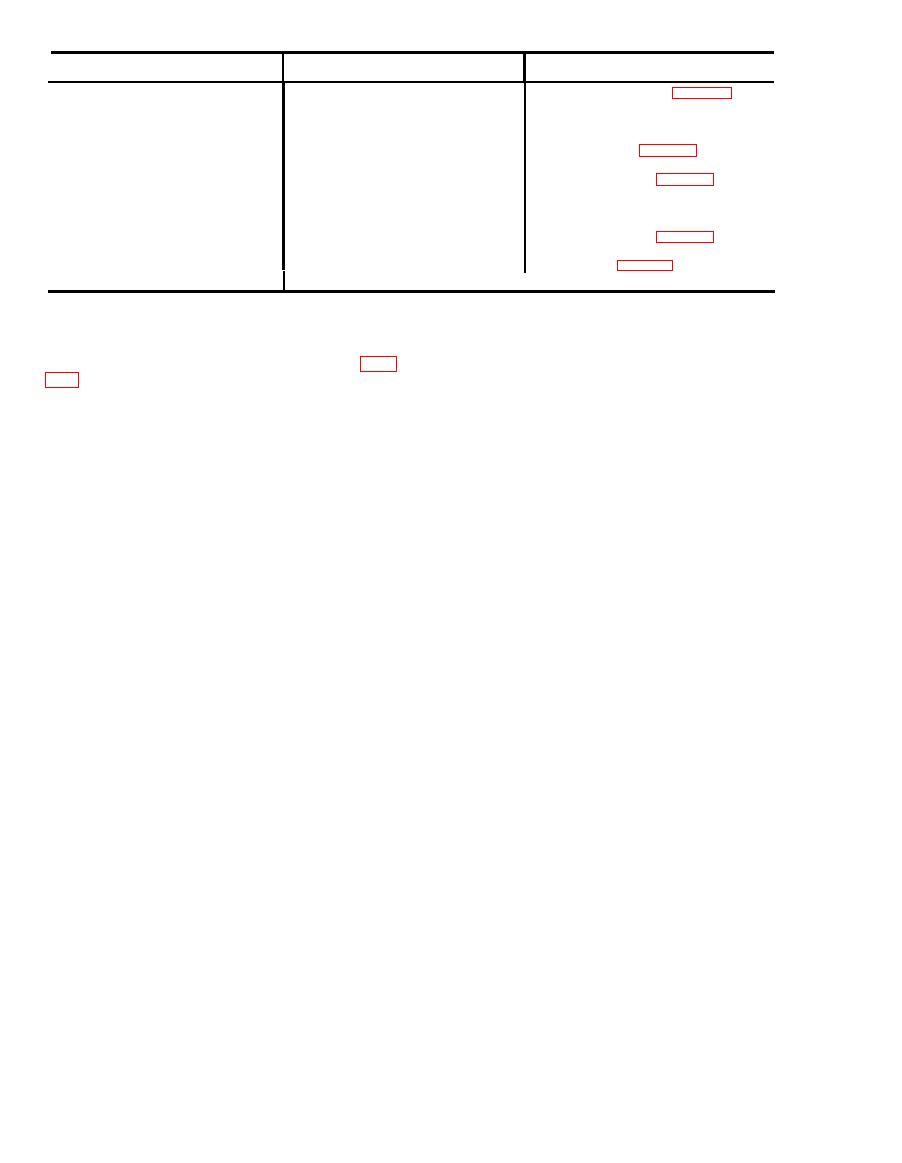

Table 3-2. Troubleshooting

Malfunction

Probable cause

Corrective action

a.

a.

Fuel line clogged.

Clean out fuel line (para 3-24).

1. Burner does not fire

Fill fuel tank.

b.

b.

Fuel tank empty.

Open drip valve.

c.

c.

Drip valve closed.

Remove and clean burner cap and

d.

d.

Burner clogged.

burner body (para 3-25).

a. Remove and clean burner cap and

a. Excessive carbon on burner.

2. Incomplete combustion

burner body (para 3-25).

b. Procure clean fuel. Flush fuel lines

b. Dirt in fuel.

with clean fuel.

a. Remove and clean burner cap and

a. Excessive carbon on burner.

3. Heater does not heat properly

burner body (para 3-25).

b. Remove stack, disassemble, and

b. Accumulation of soot in stack.

clean (para 3-21).

Heater too hot.

Reduce amount of fuel fed to fire.

4. Heater body warped.

with waterproof kraft wrapping paper (UU-P-27)

b. Inspection. Examine the item for any unusual

secured in place with tape.

conditions such as damage or missing components.

g. Marking. Mark in accordance with MIL-STD-

Inspect the heater in accordance with steps outlined

129.

in Quarterly Preventive Maintenance Services (para

rective action taken will be recorded on DA Form

2404 (TM 38-750).

c. Cleaning and Dying. Cleaning and drying by an

a. General. This paragraph provides instructions

approved technique is the first essential procedure

for preparation of the heater for limited storage, not

in any effective preservation process. Approved

to exceed six months.

methods of cleaning and drying, types of preserva-

b. Inspection and Maintenance of Equipment in

tives, and methods of application are described in

Storage. When heaters have been placed in limited

T 38-230.

storage, all scheduled preventive maintenance ser-

d. Painting. Paint surfaces where the paint has

vices including inspection shall be suspended and

been removed or damaged. Refer to TM 9-213 for

preventive maintenance inspection shall be per-

detailed cleaning and painting instruction.

formed as specified herein. Perform quarterly pre-

ventive maintenance services when the heater is

e. Depreservation Guide. Record depreservation

instructions on DA Form 2258 or DD Form 1397 as

initially placed in limited storage and every 90 days

applicable.

thereafter. Record all deficiencies and shortcomings,

together with corrective action taken, on DA Form

f. Sealing of Openings. Openings that will permit

2404. Required maintenance will be performed

the direct entry of water into interior of the heater

shall be sealed with pressure-sensitive tape conform-

promptly to insure that the heater is mechanically

ing to Specification PPP-T-60, Class 1, or covered

sound and ready for immediate use.

Section XII. DEMOLITION OF MATERIAL TO PREVENT ENEMY USE

3-33. General

(1) Exhaust pipe sections.

When capture or abandonment of the heater to an

(2) Drip valve.

enemy is imminent, the responsible unit commander

(3) Burner

must make the decision either to destroy the equip-

(4) Heater body.

ment or render it inoperative. Based on this deci-

(5) Grate

sion, orders are issued which cover the desired ex-

(6) Fuel can and hose.

tent of destruction. Whatever method of demolition is

b. Other Demolition Methods.

employed, it is essential to destroy the same vital

(1) Scattering and concealment. Remove all

parts of all heaters and all corresponding repair

easily accessible components and scatter them

parts.

through dense foliage, bury them in dirt, or sub-

merge them in a lake, stream, or other body of water.

Inoperative

(2) Submersion. Totally submerge the heater in

a body of water to provide water damage and con-

a. Demolition by Mechanical Means. Use sledge

cealment. Salt water will damage metal parts more

hammers, crowbars, picks, axes, or any other heavy

than fresh water.

tool which may be available to destroy the following: