TM 10-4500-200-13

heater assembly, heater installation, ser-

f r a y e d , worn,

or broken condition. Refer

v i c i n g , and replacement of heater com-

to organizational maintenance for replace-

ponents.

ment of guy ropes.

I n s p e c t the guy lines for evidence of a

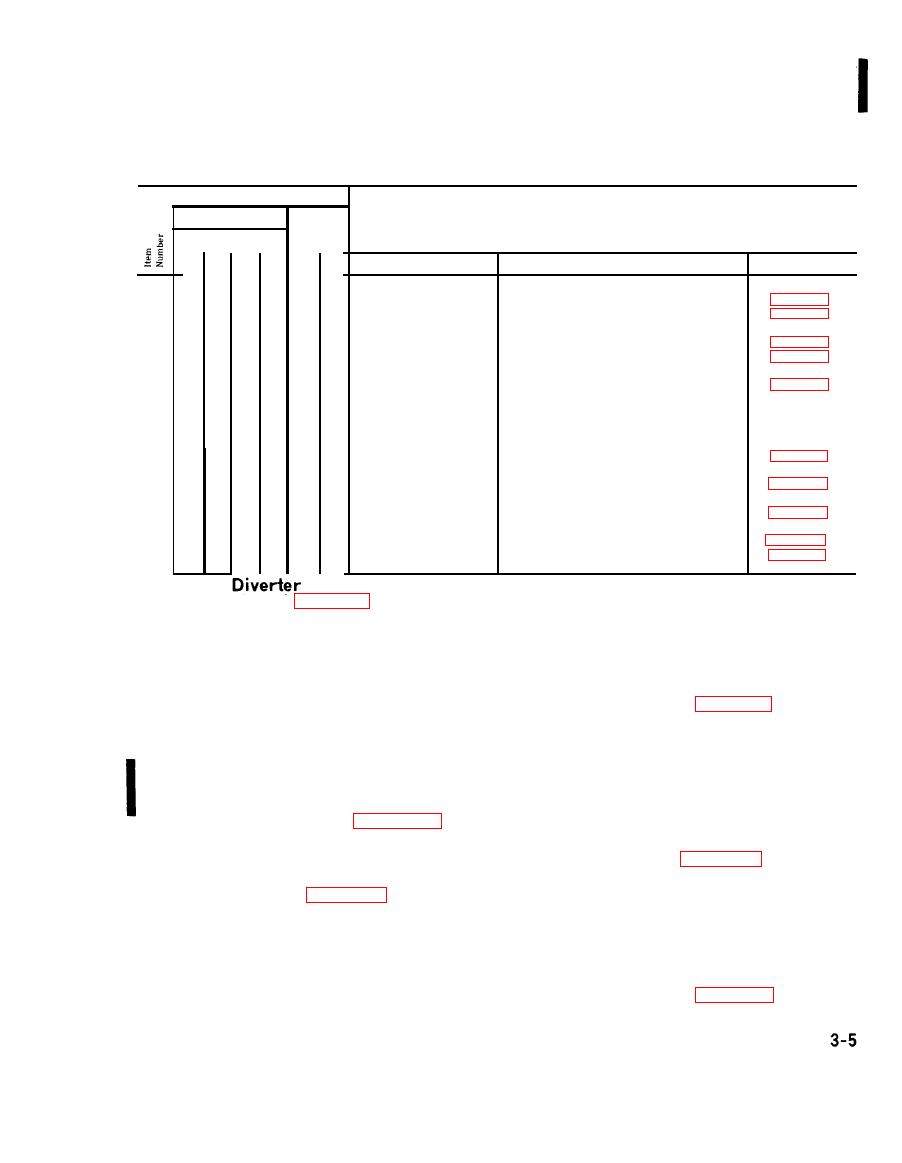

Interval

M - Monthly

B - Before operation

A - After operation

D - During operation

W - Weekly

Q - Quarterly

Operator

Org

Daily

-- -- --

--

--

Procedure

Reference

Item to be Inspected

B

D

A

w

M

Q

--

-- --

BODY ASSEMBLY

Inspect for proper alinement

X

X

Door

1

X

Clean carbon from grate

X

2

Grate

FUEL SYSTEM

X

X

X

Inspect for leaks and damage

X

X

3

Kit adapter

Inspect tube for looseness and

Vent tube

X

X

X

4

damage to tube threads.

X

X

Inspect hose for breaks and

Hose assy

X

5

Secure hose connections

X

X

X

BURNER

ASSEMBLY

Clean carbon deposits from burner

Burner

X

X

X

6

body and burner cap.

Inspect valve for leaks

X

Drip valve

7

EXHAUST SYSTEM

Inspect for

holes and clogged pipe.

Exhaust pipe

X

X

8

X

Clean soot

and carbon from pipes

X

Inspect for

holes and clogged cap

Flue cap

X

X

9

Inspect for

worn or frayed con-

X

X

10

Guy lines

dition.

b. Cleaning, Inspection and Testing.

3-20. D r a f t

(1) Clean the soot and carbon from the

connect the guy lines attached to the draft

pipe sections.

d i v e r t e r . Remove the draft diverter from

(2) Inspect the pipe section for holes,

the pipe.

dents, clogged condition, evidence of rust-

b. Cleaning and Inspection.

ing, and loose fitting joints. Replace defec-

(1) Clean the soot from the draft di-

tive pipe sections as required.

verter.

(2) Inspect the draft diverter for holes

tach the exhaust pipe sections to the space

and clogged condition. Replace a defective

heater body. Reconnect the guy lines.

draft diverter.

(3) Inspect the guy lines for service-

WARNING

ability. Refer to organizational maintenance

Fuel can must be taken down from

for replacement of the guy lines.

the support (before releasing can)

c. Installation. Refer to figure 3-1 and

to preclude fuel spillage.

install the draft diverter on the exhaust

pipe and reconnect the guy lines.

a. Removal. Refer to figure 3-2 and re-

move the adapter from the fuel can. Dis-

connect the fuel hose.

a. Removal. Refer to figure 3-1 and re-

b. Inspection.

move the exhaust pipe.

(1) Inspect the adapter for damage,

NOTE

proper assembly, fuel leaks, and a defec-

Compress t h e telescoping p i p e

tive gasket.

sections into the lower section of

(2) Replace a defective adapter.

the pipe. Rotate the lower section

of the pipe to disengage the heater

stall the adapter on the fuel can. Reconnect

body.

Change 4