TM 5-3895-377-13&P

5-32. CIRCULATING PUMP REPAIR (CONT).

Amyl acetate is a flammable solvent and should be used with care or injury could occur to

personnel.

NOTE

•

Check bushing for cracks after installation. Coat surface of the bushing with Amyl acetate

(banana oil). Let it evaporate, and any cracks will be visible as wet streaks. If cracks appear,

the bushing should be replaced.

•

Scratches on the shaft in the seal area will provide leakage paths under the seal.

•

When installing a new carbon graphite idler on bracket bushing, extreme care should be

taken to prevent breaking, as it is brittle material and easily cracked. If cracked, the bushing

will quickly disintegrate. Using a lubricant and adding a chamfer on the bushing and the

mating part will help in the installation of carbon graphite bushings.

•

An arbor press should always be used for installing carbon graphite bushings. Be sure

bushing is started straight and DO NOT STOP pressing operation until bushing is in proper

position. Starting and stopping will invariably result in a cracked bushing.

•

Carbon graphite bushings with extra interference fits are frequently furnished for high-

temperature operation. These bushings must be installed by shrink fitting. Heat the bracket

or idler to 750°F and install cool bushings with an arbor press. If facilities are not available

for this temperature, it is possible to install with 450°F temperature. However, the lower the

temperature the greater the possibility of cracking the bushing.

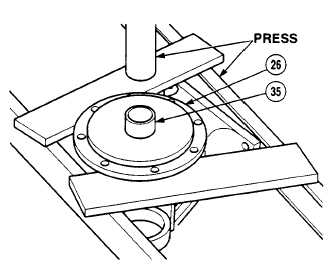

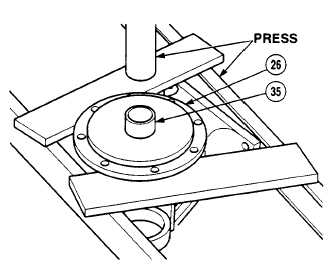

(3)

Using press, install bracket bushing (35) in

bracket (26).

5-79