TM 9-4520-251-14

5-12 CRANKSHAFT AND CAM GEAR (CONT)

Location/Item

Action

Remarks

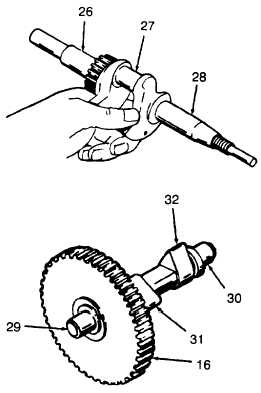

3. Crankshaft

Inspect for bend in crankshaft (2). Check for worn

gear teeth and damaged threads. Inspect keyway

for damage, Inspect for out–of–round journals (26

and 28). Discard crankshaft having any of above

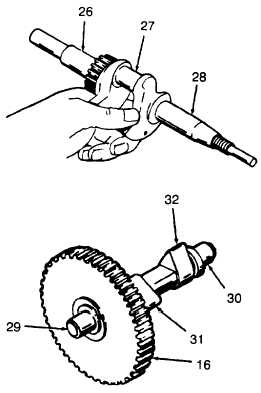

5. Cam gear

6. Journals

and lobes

defects.

4.

Journals

Journal (26) at power takeoff

end must exceed 0.998 inch

(25.35 mm) in diameter. Crank

pin (27) must exceed 0.996 inch

(25.30 mm) and journal (28) at

armature end must exceed 0.873

inch (22.17 mm). Discard crank–

shaft not meeting these

specifications.

Inspect teeth of cam gear (16)

for wear and nicks. Replace if

defective.

Journals (29 and 30) of cam

gear (16) must exceed 0.498

inch (12.65 mm) in diameter.

Cam lobes (31 and 32) must

exceed 0.950 inch (24.13 mm).

Discard cam gear not meeting

these specifications.

INSTALLATION

NOTE

It is assumed that if ball bearing was removed, new

one was installed as described in paragraph 5–11.

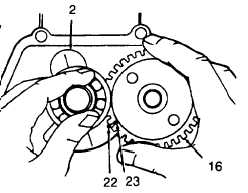

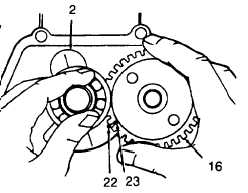

7.

Crankshaft and

When reassembling engine, if

cam gear

tappets have been removed, be

sure they are inserted first.

Align timing marks (22 and 23)

on crankshaft (2) and cam gear

(16) and insert crankshaft and

cam gear together. Refer to ex–

ploded view illustration and complete

assembly of crankshaft and cam gear.

NOTE

Install new crankcase gasket when replacing crankcase cover (1).

5-27