TM 9-4520-251-14

6-5

CRANKCASE COVER AND CYLINDER ASSEMBLY (CONT)

Location/Item

Action

Remarks

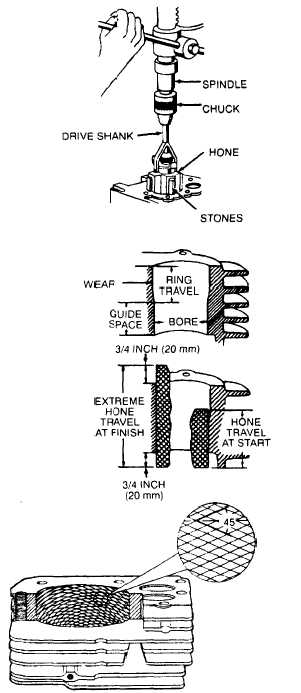

drive shank in chuck of drill press. Slip hone

into bore. Connect drive shank to hone and

set stop on drill press so hone can extend

only 3/4 to 1 inch (20 to 25 mm) from

top or bottom of bore in cylinder assembly.

NOTE

Honing can be done with portable electric drill. Set

honing plate on liberally oiled floor. Cut a wood

block and place inside of bore of cylinder assembly

as a stop for hone.

5. Honing

Tighten adjusting knob of hone with finger

or small screwdriver until stones fit snugly

against wall of bore. DO NOT FORCE.

Lubricate hone as recommended by manu-

facturer and operate at 300 to 700 rpm. As

hone spins, move up and down at lower end

of cylinder bore as illustrated. Cylinder is

not worn at bottom and will guide hone to

straighten bore. As bottom of hone in cyl-

inder assembly (4) increases in diameter,

gradually increase length of strokes until

hone travels full length of bore. Do not ex-

tend hone more than 3/4 to 1 inch (20 to

25 mm) at either end of bore. As cutting

tension decreases, stop hone and tighten

adjusting knob. Check size of cylinder bore

frequently, Hone about 0.0005 inch (0.0127 mm)

larger to allow for shrinkage when cylinder cools.

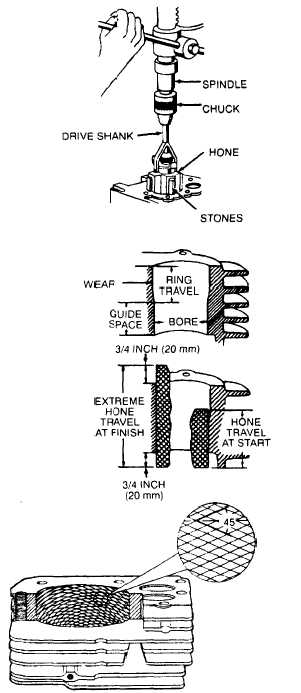

Wall of finished, resized

bore in cylinder assembly (4)

should have a crosshatch

appearance as illustrated.

Rapid movement of hone

during last few strokes

will produce this finish.

Crosshatching allows

proper lubrication and

ring breakin.

6. Cylinder bore

wall check

6-12