TM 9-4520-251-14

6-5

CRANKCASE COVER AND CYLINDER ASSEMBLY (CONT)

Location/Item

Action

Remarks

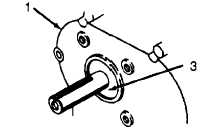

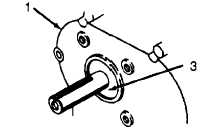

2. Oil seal in

Remove and discard defective oil

crankcase cover

seal (3). Lubricate inside diameter

of seal with Lubriplate (Appendix E,

Item 3) or equivalent before

assembly. Position sharp edge of

oil seal toward inside of engine and

press in as far as it will go. Installed

oil seal should be recessed 3/16 inch

(4.69 mm).

3.

Primary

Bore measure–

ment and

resizing

NOTE

repair of cylinder assembly consists of honing cylinder.

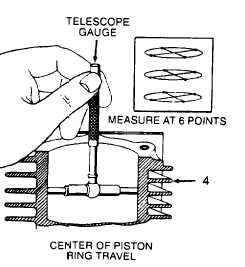

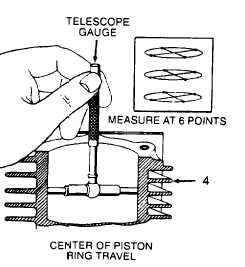

Using a telescope gauge (Appendix B,

Section Ill, Item 16)

and dial caliper (Appendix B,

Section III, Item 17), de_

termine size of bore in cylin-

der assembly (4). Take right

angle measurement at six

points as illustrated. If bore

in cylinder assembly is more

than 0.005 inch (0.13 mm)

oversize or 0.0025 inch

(0.06 mm) out of round, it

must be replaced. Standard

size is 2.5615 to 2.5625

inches (65.062 to 65.088 mm).

NOTE

Do not deglaze wall in bore of cylinder assembly if only installing piston

rings.

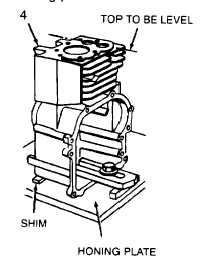

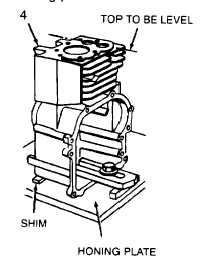

4. Honing setup

Clean bore in cylinder assembly (4)

at top and bottom to remove burrs

and pieces of head gasket. Fasten

cylinder assembly to heavy iron

bracket or use honing plate. Be

sure top of cylinder assembly is

level. Use shim if necessary.

Use level to align drill press

spindle with bore in cylinder as-

sembly. Lubricate surface of drill

press table liberally with oil (Appendix E,

Item 8). Set honing plate

and cylinder assembly on drill

press table. Do not anchor to

drill press table. Place hone

6-11